Let’s dive into some comparisons between the Baraja Spectrum-Scan™ LiDAR and our previous LiDAR solution with an emphasis on real-life on-track data and differences in approaches in our perception pipeline.

Read MoreThis Final Year Thesis by Daniel Crowe sets out to design carbon fibre wheel shells and wishbones for the 2019 Monash Motorsport racecars. His work utilised composite materials, instead of Aluminium or Steel to ensure a lighter, stiffer and more reliable design of the wheel shells and wishbones.

Rigorous testing and data analysis play a vital role in the success of our numerous FSAE campaigns. Over the years, the team has depended upon an extensive testing schedule so that we can effectively capitalise on the limited time we have before competitions. Each test contributes to our confidence as a team, in both the cars and the drivers.

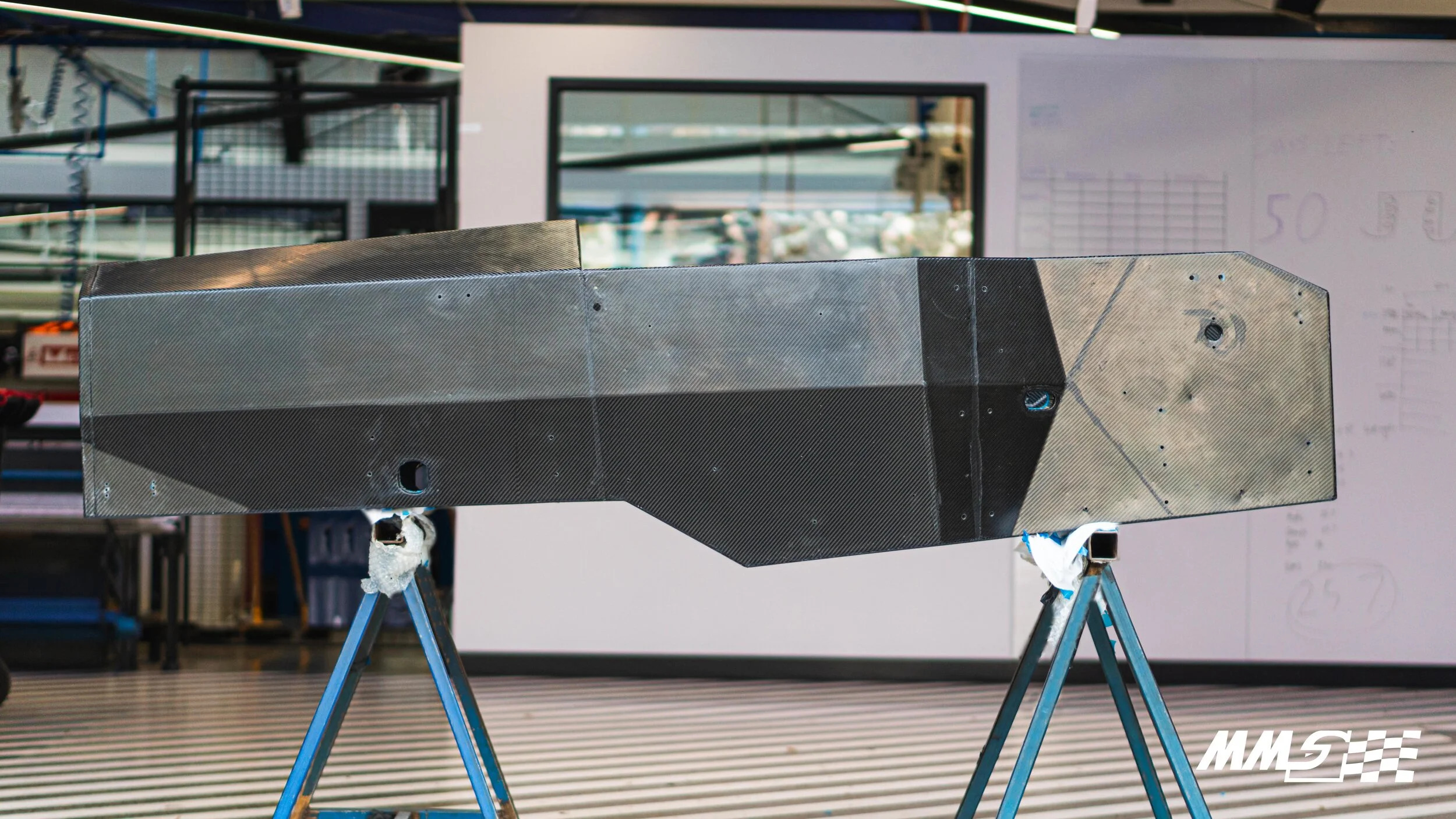

Read MoreIn 2019, we successfully implemented our first pair of carbon fibre composite monocoque chassis, replacing the tried and tested tubular steel space frame. The work presented in this report highlights this journey and is the culmination of over four years of development dating back to late 2014.

Read MoreThejana Abeykoon's Final Year Thesis highlights the importance of meticulous care and attention to detail when designing and manufacturing such a critical system on an FSAE race car.

Read MoreAero mapping is one of the methods we use to optimize our car’s performance across the lap. In addition to making aerodynamic design decisions, aero mapping also helps us tune our suspension parameters and determine optimal vehicle setup based around enhancing aero performance.

Read MoreWith all the challenges that we’ve faced in 2020 so far, FSAE Australasia 2019 truly feels like a lifetime ago. Our 2020 Business Manager Ben reflects on our 2019 competition experience

Read MoreOur opportunity to test at this world-class facility with Bosch was integral to the development of our M19 vehicles.

Read MoreHear about our first-ever Europe Campaign as One Team. Two Cars.

Read MoreEver wondered who our drivers are? Or how they train for competition?

Read MoreDecember signals the exciting period where the team is in its final stages of rigorous testing and statics practice in preparation for this year’s FSAE Australasia Competition.

Read MoreAfter several busy weeks following the end of Semester Two and plenty of anticipation by veteran and junior Monash Motorsport team members alike, Formula SAE-A 2016 was finally upon us!

Read MorePowertrain Engineer, Daniel Crouch, details the various factors and considerations taken into account when testing with a Dynamometer

Read MoreHamzah gives us a detailed overview of our approach to Aerodynamics in 2016.

Read MoreManagement of a Formula SAE team comprises of the management of people, resources and technical direction to maintain the core positive attributes of the team whilst continually generating progress and pushing boundaries on every level.

Read MoreWith the introduction of new rules for 2015, Monash Motorsport’s Aerodynamics section has returned to a ground up design philosophy for this year’s aero package.

Read MoreThe design of M15 started last year with the release of 2015 FSAE rules, which drastically changed the parameters to which we have to design the car.

Read MoreWith 30% more power and over 25% more torque, our new turbocharged car is proving a little hot to handle for the drivers. Luckily we have recently been testing Traction Control (TC) setups for use with our MoTeC ECU.

Read More