Monash Motorsport is proud to be supported by T.I. Performance, whose expertise and products help us push the limits of performance, reliability, and data precision. T.I. Performance is well known for their wide range of automotive sensors and performance parts. Their generous contribution to our design is in the form of linear potentiometers, a type of sensor which varies its output based on movement in one direction.

Read MoreThe monocoque is the backbone of our Formula SAE car - a full carbon chassis that provides the strength, stiffness, and safety essential for high performance. In order to manufacture such a complex structure, accuracy is everything. Every hatch, cut-out, and mounting feature must hold its shape throughout the curing process, where extreme pressure and temperature can easily cause distortion. To achieve this, Monash Motorsport relies on highly specialised tooling known as monocoque plugs.

Read MoreFormero has been a proud sponsor of Monash Motorsport, providing us with world class 3D printing services for almost a decade. Formero prints M24’s custom motor shrouds, which protect critical wiring ensuring reliable functioning of the motors. Reliable motor power delivery and feedback ensure that M24’s motors are running as intended, so it is important to avoid these processes being interrupted.

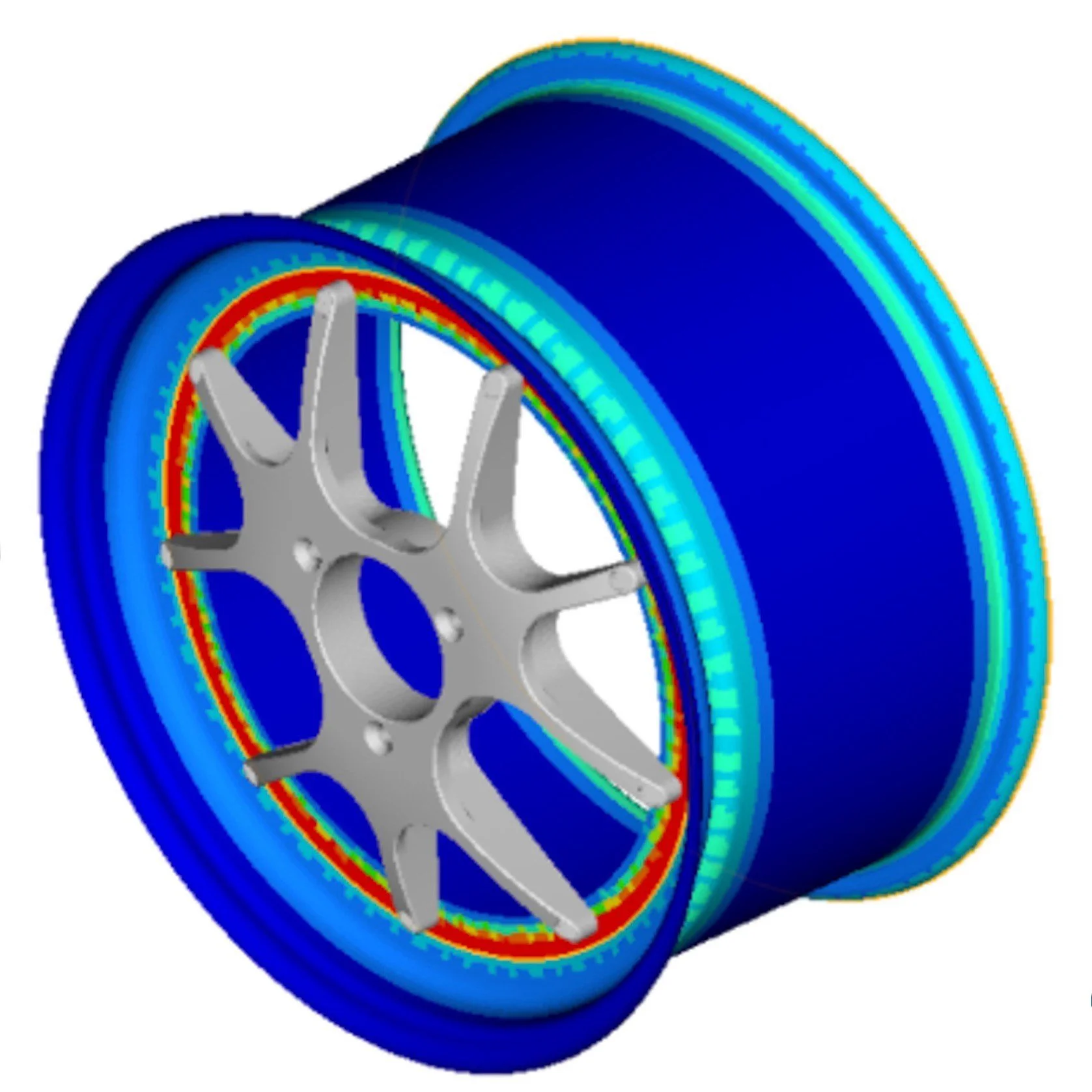

Read MoreBefore manufacturing any structural component of our car, rigorous analytical calculations must be conducted to justify the engineering choices made. However, the equations and theoretical models governing these calculations are inherently simplified and fall dramatically short of capturing the true complexities of real life. This is where the Altair’s Finite Element Method softwares and tools prove invaluable.

Read MoreFormero has been a partner of Monash Motorsport for many years, and are renowned for their high quality 3D Printing services. Our aerodynamic wing profiles require end caps for assembly of the carbon fiber skins and to transfer loading to the mounting structure. They have to be lightweight, yet stiff enough to pass deflection rules. As such, end caps are highly important components of our car that enable our aerodynamic package to be suitably attached to the vehicle.

Read MoreThe overheating of our vehicle’s motors and inverters can cause permanent damage to the critical components within our powertrain. To effectively cool M23’s Fischer motors, we use custom cooling jackets designed by our engineers. Motor power delivery and feedback are also critical to the reliable functionality of our motors, and to ensure these aren’t interrupted, we utilise custom motor shrouds to strain-relieve these critical connections between components in the powertrain.

Read MoreIn autonomous driving, the motion planning subsystem is required to determine a feasible state and control trajectory to navigate the vehicle to perform a specific task. Kerry He’s thesis presents an implementation of a receding horizon planner (RHP) to perform motion planning for Monash Motorsport’s autonomous racecar to compete in the Formula Student Driverless competition.

Read MoreThe design of a path planning and control algorithm for a formula student vehicle is one of the key milestones to competing in driverless competitions. Adam Slomoi’s Final Year Project takes us back to the team’s beginnings for autonomous driving, from optimal race line computation to control.

Read MoreLet’s dive into some comparisons between the Baraja Spectrum-Scan™ LiDAR and our previous LiDAR solution with an emphasis on real-life on-track data and differences in approaches in our perception pipeline.

Read MoreDelivering on the challenge of manufacturing our most complex aerodynamic package yet would not have been possible without the help of C5 Systems and Austuf . The article highlights this partnership through which we can challenge ourselves to actualize complex aerodynamic packages such as M21’s.

Read MoreIn early 2021, as we continued to work from home, we depended more heavily upon digital platforms to develop both the team and our 2021 driverless-electric challenger. So our team saw a unique opportunity to deepen our knowledge of the tools at our disposal and put our rendering tool of choice, Keyshot, to the ultimate test.

Read MoreNext up on our blog series, we take a look at how Baraja has helped us with simplifying our autonomous systems pipeline through software and hardware integration. Tune in as Chris and Rashmidha take us through how low voltage integration and software-definable scan patterns that can be implemented seamlessly with Baraja’s continual support.

Read MoreIn 2016 Cameron Warne based his final year project on integrating existing models into an easy to use simulator that allows both current and future team members to make informed decisions and increase the cars performance. Read about the genesis of our computer modelling system in Cameron’s Final Year Project.

Tune in for the latest edition of our blog series where Head of Autonomous Systems, Jordan Esh, takes a deeper dive into the simulations and analysis that reinforced Baraja Spectrum-Scan™ as the right LiDAR choice for the team.

Read MoreTune in to the first edition of our brand new blog series, Baraja and Monash Motorsport, where Head of Autonomous Systems, Jordan Esh, highlights the key reasons that motivated our exciting new partnership.

Ryan Ockerby’s Final Year Thesis helped us to design our aerodynamics package with greater confidence and allowed for a greater number of designs and investigations. His project aimed at improving our aerodynamic package design process by using faster solving CFD simulations running in conjunction with highly complex cornering CFD simulations, quality wind tunnel modelling and data acquisition to improve on-track testing.

In 2019, our electric vehicle, M18-E, was retrofitted with sensors, computing units and actuators to become the first ever Driverless car we have produced, M19-D. Georgia Ovenden’s 2019 final year project contributes to the perception systems for our driverless FSAE vehicle.

Read MoreThis Final Year Thesis by Daniel Crowe sets out to design carbon fibre wheel shells and wishbones for the 2019 Monash Motorsport racecars. His work utilised composite materials, instead of Aluminium or Steel to ensure a lighter, stiffer and more reliable design of the wheel shells and wishbones.

This project includes a broad range of work and investigations into improving the understanding of and techniques involved in designing and fabricating a high-performance Formula SAE/Formula Student exhaust system.

Read More