The Centre of Attention

In 2020, part designer Cooper Morrison was tasked with the design of the wheel centres. Here is a brief snapshot of his design experience.

The first stage in the design process for the 2020 iteration of the 13” wheel centres was conducting extensive research. As this design had to be compatible with our M19 vehicles this somewhat limited the scope of the design iteration process, however I was still determined to find performance gains for the part through optimisation. I conducted research into solutions implemented by FSAE teams around the world, other motorsport disciplines and industry in general. From this research I gained an understanding of the different design approaches that can be taken for the part and next turned to academic papers, the team’s past designs and other material to learn the fundamentals of wheel centre design.

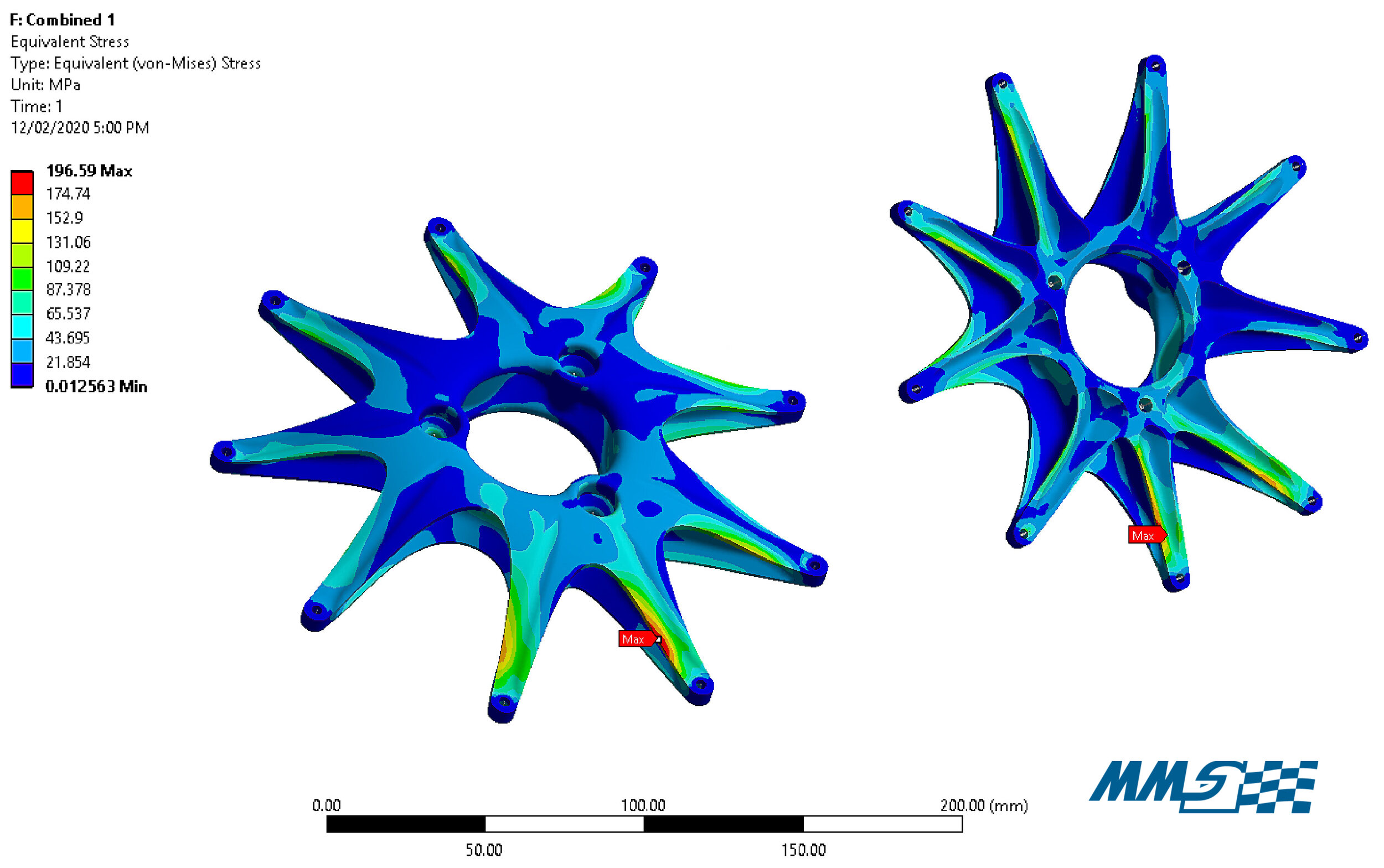

After determining the most influential, performance metrics for the part (stiffness and mass), I began my concept generation stage. Here I spent the majority of my time creating CAD based on expected load cases and the fundamental principles that govern this part of the car. This included testing geometries to provide a stiff and lightweight solution whilst withstanding the anticipated forces calculated over the target part lifespan.

This process involved creating a potential design, importing the design into ANSYS Finite Element Analysis Software and observing how the design performed under predicted loadings. From here, I would iterate on the design for a given number of cycles, assess the design’s strengths and weaknesses and move on to the next design.

Implementing this rapid design generation strategy in the early concept phase allowed me to come up with multiple solid concepts before moving onto further refinement and optimisation. It was essential to keep track of each concept in an organised manner with a measure for comparison; a theoretical points gain or loss calculation of each design at competition. This enabled fast and efficient concept creation, making it easy to analyse several designs and see how they performed in comparison to each other. After finalising my concept generation to a select few designs, I began to consider in much more detail the manufacturability of the potential part. For help in this regard, I turned to Andrew from Wirawaji, a long time sponsor of the team who specialises in machining.

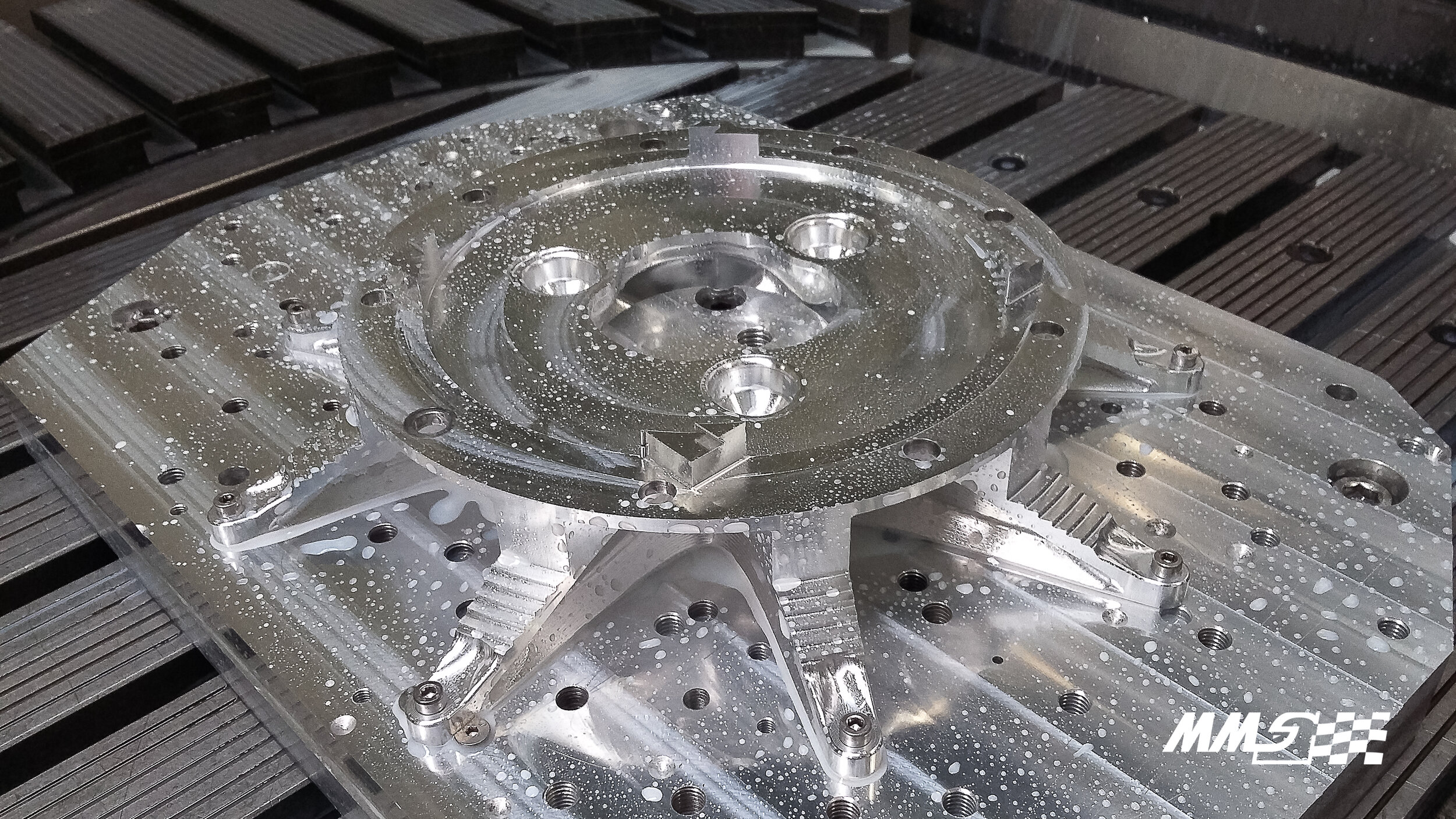

I spoke frequently with Andrew from Wirawaji to discuss the manufacturing constraints on potential designs. It was critical to maintain this close working relationship to ensure the part was optimised for Wirawaji’s 5-axis CNC machine. Where 3-axis is very limiting, 5-axis presents a challenge in creating a design that will truly utilise the extra degrees of freedom to produce the best design possible. Enabling you to rotate and tilt the part as well as operate in the standard x-y-z axis, 5-axis machining allows access to areas of the part that would previously have been near impossible or taken an infeasible amount of time to jig and setup.

Andrew worked closely with me to offer assistance while refining and optimising concepts Our design targets throughout were to create a part that was 800 grams, with a stiffness target of 0.12 degrees/g, whilst maintaining an optimised design for 5-axis machining. Andrew’s considerable experience and passion for engineering design taught me a lot during this time, enabling us to produce a final concept that showed very high potential. Combining simple beam theory with surface CAD, this design was highly efficient with its use of mass (exceeding the target at 731 g) to produce maximised stiffness.

Final adjustments and FEA iteration were conducted to integrate the wheels centres with the larger assembly, as well as to extract as much performance as possible before the design deadline. The final product is one of the most visually stunning and highest performing structural components MMS has seen.

![20200409_230324[1].jpg](https://images.squarespace-cdn.com/content/v1/5e2a78aea2dc434ac475b5a4/1598583356772-VEZ0FFG1GD9HJEYTRL85/20200409_230324%5B1%5D.jpg)